EDM (Electrical Discharge Machining)

Wire & die sinking erosion machines from renowned manufacturers

What is spark erosion?

Spark erosion, also known as spark machining or electrical discharge machining (EDM), is a manufacturing method during which a preferred shape is achieved through the use of electrical discharges, i.e. sparks. In other words, it is a metalworking process where an electrical discharge is produced between two conductors, while a dielectric fluid is used to insulate the workpiece from the electrode. An electric discharge machine, or a spark erosion machine, is used for the removal of electrically conductive materials on a workpiece through evaporation or chipping. In order to make this possible, EDM machines can only process workpieces that are made out of some very strong electrical conductor, such as tungsten, copper, graphite, etc. and as such can serve as electrodes.

Removal of the conductive material of a workpiece

Processes include evaporation or chipping

Precise contours can be achieved in the shape and dimensions of the workpiece

Quality Great offers Personalized

How does an electric discharge machine operate?

During the erosion process conducted with an EDM machine, an electrical discharge occurs between the electrode and the workpiece, thus creating sparks that simultaneously fuse and evaporate the workpiece. An electric discharge machine removes the material from the workpiece through a sequence of such fast, repeated current discharges between the two electrodes (the tool-electrode and the workpiece-electrode), which are separated by a dielectric liquid and are subject to an electric voltage. In order for the process to take place, it is essential that the EDM machine tool does not make actual contact with the workpiece; this is achieved through the use of a dielectric fluid, which restricts the electrical field and ensures that the removal of material from the workpiece by a spark erosion machine is done in a controlled way. The dielectric fluid has to be a non-conductive fluid, like oil or deionised water. All metals and metal alloys can be processed using this method, although EDM machines are mostly used with aluminium, brass, copper and steel. The process of spark erosion also works with other conductive materials like graphite and certain ceramic materials.

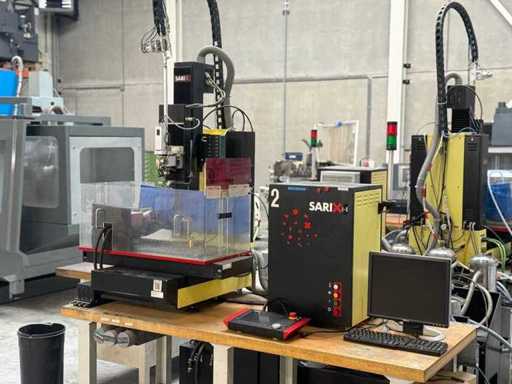

EDM machine in use

Special types of EDM machines and their application

A special type of EDM machines is a die sinking machine, with which a workpiece is put into a dielectric fluid. Die sinking is a technology used in tool manufacturing for the construction of castings, bending punches, and moulds. Another special application of the EDM machine is in EDM drilling and threading of initial holes. This is used as a process step before wire eroding, another type of spark erosion achieved through the use of an electric discharge machine. Wire eroding acts as a cutting process, during which a wire is fed through the workpiece and then, using an electrical current, the workpiece is brought to a melting point. The dielectric is sprayed onto the workpiece using a hose. The advantage of erosion is that all conductive material of any level of hardness can be processed with an adequate spark erosion machine. The worked contours are of the highest precision in their form and dimensions.

Affordable used EDM machines from well-known manufacturers

Some of the well-known EDM machine manufacturers are AGIE CHARMILLES, ONA, AGEMA and OPS INGERSOLL, which also produce fully functional wire erosion machines, die sinking machines and start-hole erosion machines. A conventionally-steered spark erosion machine or a modern CNC EDM machine for sale can often be found in good condition here at Surplex and we also occasionally offer high-quality used EDM machines in our industrial auctions at a competitive price. Due to a continuously changing machine offer we recommend to regularly visit our second-hand EDM machines page in order to find the preferred used EDM machine for your needs, as well as to visit our auction page and other machine pages, and browse through the rest of our offer.