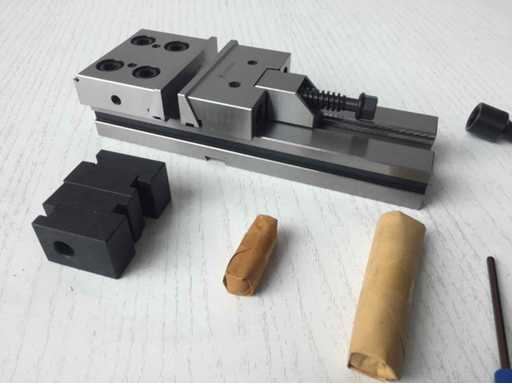

Machine Vices

Securely fix workpieces before milling, drilling, etc.

Using a machine vise in industry

A machine vise is necessary to clamp in a workpiece. This is the case for all types of machine tools, no matter if it is a drilling or milling machine. Machines, where the workpieces rotate, use a clamping device with a rotating chuck. The machine vise is generally much more precisely produced than a normal vise. Thereby, it has a stronger clamping force.

Clamping in of a workpiece for processing

Various forms depending on the workpiece

Used in machining processes, workpiece and fixture construction

Quality Great offers Personalized The operation of a machine vise can be done manually, hydraulically or pneumatically. For NC and CNC-machines there are special types of vises. An important criteria of a vise is its clamping jaws. These can be switched and adjusted. A stable body supports the fixed clamping jaw. The movable clamping jaw travels along tracks, which is moved using a threaded spindle. On machine vises, this is a trapezoidal screw. Various forms like the normal parallel vise, swivel vise, revolving vise and the folding vise are common. A machine vise is accurately clamped onto the machining table using slots and sliding blocks. These sliding blocks ensure the precise alignment of the vise. Clamping jaws of various sizes are available.

History and development of the machine vise

A machine vise has been available since the first machine tools have been developed. The vise has a much older history. Vises have been used for a long time by blacksmiths. These were very similar to the construction of the current machine vises. A machine vise is more precisely manufactured and available in a variety of forms. With the introduction of NC and CNC-technology, the hydraulic and pneumatic machine vises were brought onto the market. These allow for the quick and automatic switching of tools, which allowed for the introduction of a loading system and can be operated through the use of a control panel.

Areas of application and examples of machine vises

In general, machine vises are used in machining processes, and tool and fixture manufacturing industries. Various sizes and special applications are common. For CNC-processing, hydraulic or pneumatically operated machine vises are used to make the process automatic. In the production of tools, special applications are used. These can be adjusted in relation to its own centre and be tilted to realise certain angles. With the processing of cutting tools, the individual segments of the cutting plate are conically milled into specific angles and after the hardening of the cutting surfaces, ground into very small angles. This is done by adjusting the vise using gauge blocks, which are available in graduations of a hundredth of a millimetre.

Manufacturers of machine vises

Several companies have specialised in the manufacturing of machine vises. Some of the most recommended suppliers include RÖHM, BEMATO, UWM, TOOLPOWER, UBK, AWM, HILMA RÖMHELD and OPTIMUM