Wire EDM Machines

For industrial eroding with wires and electricity

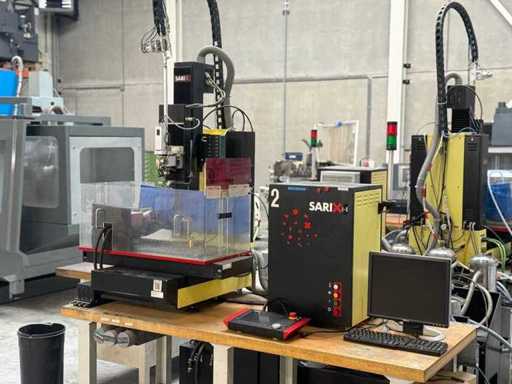

"Wire EDM Machine"

A wire EDM machine is an industrial machine that is used to cut highly precise shapes and structures into metal plates. They are used to produce injection and press moulds, profiles and dies. Without wire EDM machines, mass production in the fields of metal reforming and plastic products would not be possible.

Used to cut highly precise shapes and structures

Material is taken out of a workpiece using the help of a wire and a strong current

Its operation of a wire EDM machine should only be conducted by experts.

Quality Great offers Personalized

Creative demolition using sparks

Since the invention of electricity, it is known that sparks can leave marks on metal surfaces. The cutting effect of electric arcs was only first researched in detail in 1770 by the British scientist, Joseph Priestley. The idea of finding a practical use for it arose over 170 years later. Two brothers from Russia, B.R. and N.I. Lazarenko, researched electric discharging as a new processing method for metal surfaces. They discovered the technological basis for further utilisation. In 1969 the first machine used for wire eroding was available on the market, and since then it is a standard piece of equipment for industrial parks and tool manufacturers

ONA Wire EDM machine in use

The removal of wire

Erosion is practically the opposite of build-up welding. Instead of applying a piece of material on the present workpiece, material is taken out of a workpiece using the help of a wire and a strong current. The removal of the material occurs through electrical evaporation within a small space. Even though this causes a lot of visible sparks, these will have no damaging effect on the surface of the workpiece. The wire and workpiece are charged differently. The removal of material will always take place, where the smallest space between anode and cathode occurs. This is how highly precise contours are manufactured. In order to avoid burn damages to the wire and the workpiece, the erosion process takes place in a conductive liquid medium. The production of eroded workpieces can only be undertaken by workers with several years of training or extensive internal schooling or experience. The operation of a wire EDM machine should only be conducted by experts.

Manufacturing process

The endless wire can be fixed onto a 5-axis head, which is used to erode highly complex forms. Complex and technically challenging products can be produced during mass production using this process. Despite the high levels of complexity and the high training requirements, in regards to the manufacturing of tools, wire EDM machines are more efficient than CNC milling machines. This is particularly true as the erosion process is done contact-free. No wear and tear occurs on the processing tools, besides the cutting wire. Due to the contact-free process, the workability of the workpiece depends on its own material characteristics, particularly how hard it is.

Suppliers of Wire EDM Machines

The most well-known manufacturers are FANUC, CHARMILLES, MITSUBISHI or AGIE.