Centres d'usinage CNC (bois)

Machines CNC pour le travail du bois - des meilleures fabricants

Présentation d'un centre d'usinage CNC ou router CNC

Le centre d'usinage CNC ou le router CNC permet d'intégrer au sein d'une seule machine plusieurs opérations de découpe et de formage du bois, sous la conduite d'une commande logicielle.

Sa spécialisation croissante le rend peu à peu incontournable dans les industries de transformation, où il assure le traitement en un seul passage de pièces complexes ou encombrantes.

Intègrent plusieurs opérations de découpe par guidage numérique ou informatique

Améliorent la qualité et la vitesse de fabrication de pièces délicates

Existent en de nombreux modèles, spécialisés selon le produit fini

Qualité Grand choix Personnalisé

Le centre d'usinage à bois CNC peut regrouper les opérations de sciage, de ponçage de découpe ou de gravure. L'usinage CNC du bois fait appel à de nombreuses techniques et ne cesse d'évoluer. Ainsi la découpe CNC du bois se fait principalement à l'aide de scies pilotées par ordinateur, ou directement par jet d'eau à forte pression. Cette technique CNC pour machine à bois est de plus en plus répandue car elle permet de faire des découpes mais aussi des gravures et finitions en ajustant la force du jet d'eau.

Véritable imprimante 3D du bois, l'usinage CN permet de former une pièce à partir de bois brut avec une intervention minimale de l'opérateur. Ce qui diminue les coûts de production et accélère la vitesse de la chaîne industrielle. La diversité d'outils qu'on peut monter sur un routeur CNC à bois fait que celui ci est souvent produit sur commande pour répondre aux besoins spécifiques d'un industriel, ce qui peut en faire une machine à bois coûteuse.

Comment acheter une machine CNC à bois d'occasion

Lorsque l'on cherche à s'équiper de machines industrielles, il faut prendre en compte deux facteurs: la qualité et le prix de la machine. Pour parvenir au meilleur compromis, il peut être intéressant d'acquérir une machine CNC d'occasion.

Le centre d'usinage à bois d'occasion présente plusieurs avantages. Sont coût bien évidemment, mais aussi sa longévité s'il a été bien entretenu. Comme ces machines sont souvent produites à la demande pour les industriels, il ne faut pas hésiter à étendre sa recherche.

Pour trouver un routeur CNC d'occasion qui répond à ses besoins, le plus intéressant est de se tourner vers les ventes aux enchères de matériels industriels. Des sites Internet spécialisés dans ce type d'enchères revendent les machines d'occasion des industriels qui ferment leurs portes ou qui renouvellent leur parc.

Utilisation d'un router CNC

Le centre d'usinage CNC automatise le traitement des panneaux et des plaques de bois, tout en améliorant la productivité et leur vitesse de fabrication. Ces centres réduisent en effet le nombre de passes nécessaires, tout en éliminant la plupart des opérations de transformation complémentaires.

Leur commande informatique assure une excellente précision ainsi qu'une répétition de qualité de leurs performances. Elle autorise même une association avec la conception assistée par ordinateur, offrant un raccourcissement des délais de mise sur le marché des produits.

Ces machines se révèlent par conséquent idéales pour le façonnage d'éléments délicats, tant en dimensions qu'en complexité de fabrication, à l'image d'ensembles d'huisserie, comme les portes et les fenêtres, ou de parties de meubles.

La découpe CNC du bois est donc très utilisée chez les professionnels qui font de la menuiserie et de l'ameublement à destination du grand public. Mais on la retrouve sur toutes les étapes de la transformation du bois.

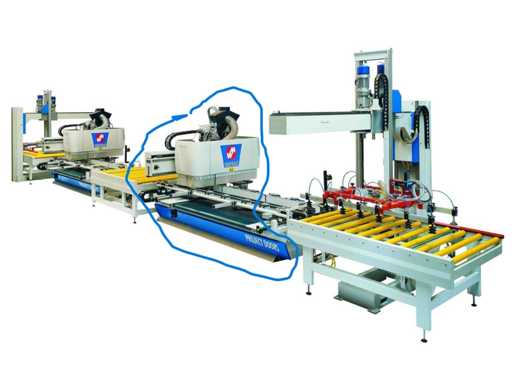

Centre d'usinage CNC en action

Mode de fonctionnement d'un centre d'usinage CNC

Le centre d'usinage CNC repose sur la combinaison d'un ou plusieurs porte-outils, d'une table de travail horizontale et d'un poste de conduite logiciel. La liberté de mouvement sur au moins 3 axes accordée au matériel d'usinage par l'intermédiaire de bras, de portiques ou de servo-commandes autorise l'accès à toutes les faces de la pièce de bois.

Suivant les instructions informatiques prédéfinies et localisées dans les 3 dimensions du plan, là ou les têtes d'usinage assurent en une ou plusieurs passes le façonnage de l'élément travaillé, solidement maintenu sur la table d'usinage. Pour assurer sa prise et s'adapter à tous les bois, cette dernière recourt à un système de succion par vide d'air, éventuellement renforcé d'un rainurage à sa surface extérieure.

Les outils qui peuvent être fixés sur un centre d'usinage CNC pour bois diffèrent en fonction de la tâche à accomplir. Scie et jet d'eau pour la découpe, perceuse et fraiseuse pour les finitions. Le routeur CNC pour la découpe du bois peut être monté horizontalement ou verticalement et est parfois entièrement caréné. La machine est alimentée par un opérateur qui peut être aidé par un entraînement.

Fabricants

Équipements complexes, à la croisée de la découpe, de l'automatisation et de la robotique, ces machines sont commercialisées par des entreprises spécialisées dans le façonnage et l’usinage du bois.

HOMAG, HOLZ-HER, MAKA, WEEKE, PADE, SCM, WEINIG et BIESSE figurent parmi les intervenants les plus connus. CMS, MORBIDELLI ou MASTERWOOD en proposent également des modèles, souvent de plus petite taille.

Achat

Sur Internet, notamment dans la sphère des machines CNC d’occasion, il est possible d’acheter à prix réduit une unité fonctionnelle de découpe CNC tel qu’un centre d'usinage CNC à bois d’occasion. Grâce à sa puissance et à son interface numérique intuitive, cette unité optimise durablement la productivité des ateliers.

Pour acquérir une machine CNC routeur à un prix avantageux, il vaut mieux passer par internet. La diversité des machines en circulation permet vraiment de trouver le routeur CNC d'occasion qui répondra à ses besoins. Le centre d'usinage à commande numérique à bois d'occasion peut se trouver auprès des industriels de la menuiserie, du panneautage et de l'ameublement, et plus rarement auprès d'artisans du bois. Les ventes aux enchères de leurs matériels permettent ainsi de mettre la main sur un routeur CNC comme machine à bois d'occasion.

Pour être le premier informé de toutes les opportunités sur les centre d'usinage CNC à bois à but industriel d'occasion, inscrivez-vous à la newsletter de Surplex.