Tomorrow 9 Mar 26

- 168Technik-Auktion: Notebooks, Drucker & MonitoreSustrum, DE

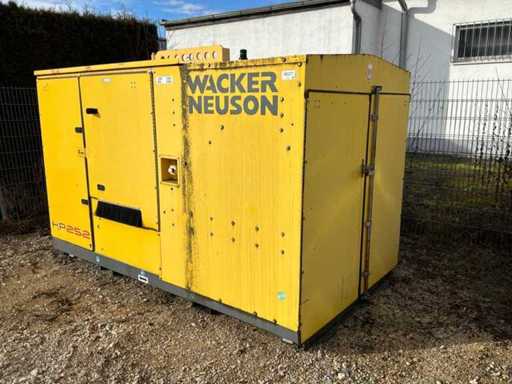

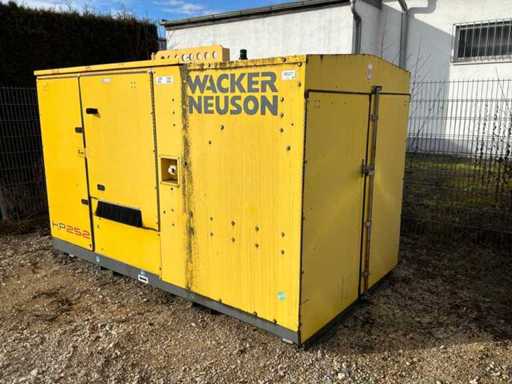

- 2High-quality machines from the construction industryMultiple locations (2), AT

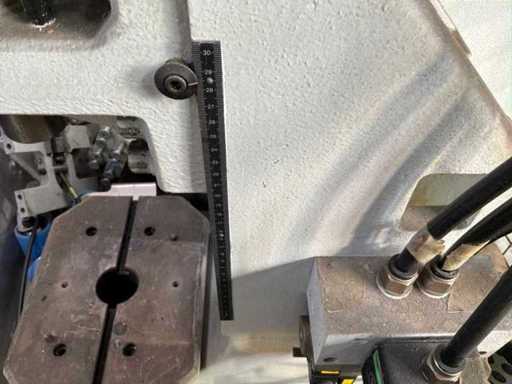

- 1DMG DMC 70H Duoblock + RS4 CNC Machining Center (2006)Multiple locations (3), DE

- 100Batches of tools and PPE suppliesRoosendaal, NL

- 1Morbidelli CNC Nesting Center & Gold Pack Pallet Wrapping Line – SloveniaŽelezniki, SI

- 242Machinery parts, industrial and electrical components due to warehouse clearanceRoosendaal, NL

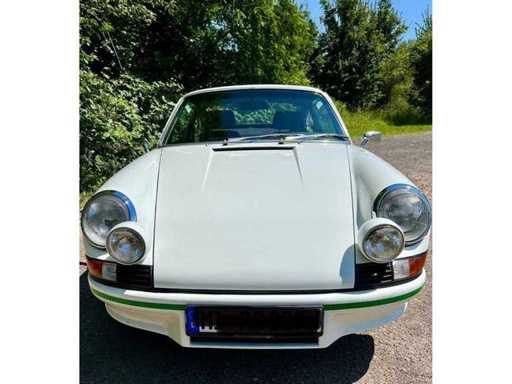

- 9D | Cars, scooters, trailers and body partsSchierling, DE

- 15D | KUKA Industrial RobotsBarsbüttel, DE

- 94Commercial vehicles and trucksMultiple locations (58), BE