1 / 23

OKUMA - LU15 - CNC Lathe with Bar Feeder FMB Turbo 5-42 XT - 2006

- Current bid

- Status

€

Total bid amount

See total breakdown

Total bid amount

See total breakdown

€

Max bid amount

See total breakdown

Max bid amount

See total breakdown

Lot specifications

- Quantity

- 1

- Margin

- No

- Brand

- OKUMA

- Type

- LU15

- Year of build

- 2006

- Serial number

- 1983

- Turning Ø

- 62mm

- Turning length

- 600mm

- Number of tool changer stations

- 20

- Chip conveyor

- Yes

- CNC control, brand, type

- Okuma OSP-U100L

- Engine power (kW)

- 22kW

- Manual present

- Yes

- Machine weight

- 5500kg

- Dimension l

- 7500mm

- Dimension w

- 1800mm

- Dimension h

- 2100mm

- Terms of delivery

- Loaded on truck

Description

Series Number: 1983

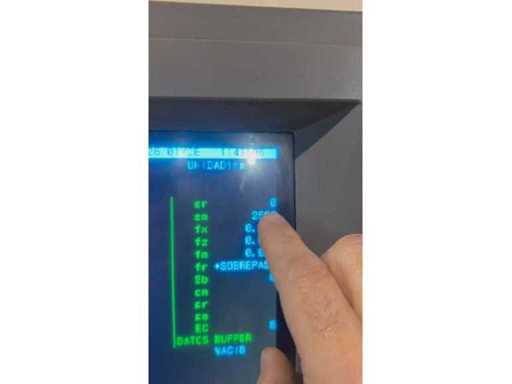

Control: Okuma OSP-U100L.

Turret technology: VDI 40.

Number of stations: 12.

X-axis travel: 260 mm.

Z-axis travel: 640 mm. Tool holder II (X/Z):

Turret technology: VDI 40.

Number of stations: 8.

X-axis travel: 140 mm.

Z-axis travel: 615 mm.

Tool holder system: Kennametal KM40. Distance between centers: 600 mm.

Fast forward: 20 m/min.

Tailstock barrel diameter: 90 mm, travel: 120 mm.

Monitor replaced by LED screen.

Floppy disk emulator installed.

Retrofit completed: refurbished guides and replacement of all turret seals (approx. 120 pieces).

Includes Chip Extractor.

Note: Tools and tooling

are not included Only 12-15 test parts were machined from aluminum in the last 5 years.

Machine inspected by Okuma in December 2025, no active alarms. Includes: FMB Turbo 5-42 XT 2001 Bar Feeder Bar capacity from 5 to 42 mm.

It works in line with Okuma CNC lathe.

Equipped with manual control panel and emergency stop.

Clutch system requires repair Load dimensions 4000x700x1500 mm 600 kgs approx

Control: Okuma OSP-U100L.

Technology: Motorized spindle.

Speed: 4,500 rpm.

Maximum power: 22 kW.

Maximum torque: 412 Nm.

C-axis: 0.001°.

Bar capacity: 62 mm.

Plate: Clamp holder.

Turret technology: VDI 40.

Number of stations: 12.

X-axis travel: 260 mm.

Z-axis travel: 640 mm. Tool holder II (X/Z):

Turret technology: VDI 40.

Number of stations: 8.

X-axis travel: 140 mm.

Z-axis travel: 615 mm.

Tool holder system: Kennametal KM40. Distance between centers: 600 mm.

Fast forward: 20 m/min.

Tailstock barrel diameter: 90 mm, travel: 120 mm.

Monitor replaced by LED screen.

Floppy disk emulator installed.

Retrofit completed: refurbished guides and replacement of all turret seals (approx. 120 pieces).

Includes Chip Extractor.

Note: Tools and tooling

are not included Only 12-15 test parts were machined from aluminum in the last 5 years.

Machine inspected by Okuma in December 2025, no active alarms. Includes: FMB Turbo 5-42 XT 2001 Bar Feeder Bar capacity from 5 to 42 mm.

It works in line with Okuma CNC lathe.

Equipped with manual control panel and emergency stop.

Clutch system requires repair Load dimensions 4000x700x1500 mm 600 kgs approx

Remarks

All items are sold as used and unchecked, an inspection can be made by appointment in advance of the auction, contacting elisabeth.deprada@surplex.com.

Additional details

Todos los artículos son vendidos como usados y sin comprobar, se puede hacer una inspección bajo cita previa anticipada a la subasta, contactando con elisabeth.deprada@surplex.com.

NOTA

Los artículos se encuentran en diferentes ubicaciones y la lista se va actualizando (ver las descripciones de los artículos)La coordinación de las recogidas debe ser con cita previa .

Algunos artículos cuentan con desmontaje y carga, se indica en el apartado "coste adicional"

Fecha límite de pago: 06/03/2026

Video

See the details and take a closer look at the item in this video.

Documents

39,414 kg

CO₂e

This is the amount of CO₂ emissions you could save by purchasing this item pre-owned instead of new.For comparison, an Berlin - Lisbon flight corresponds to 169 kg CO₂e per passenger.